Waveguide Terminations - Sliding Adjustable |

|---|

Adjustable Sliding Waveguide Terminations

The 721 series sliding terminations are used in laboratory high precision measurements. They are also ideal for field measurements and production setups requiring low VSWR.

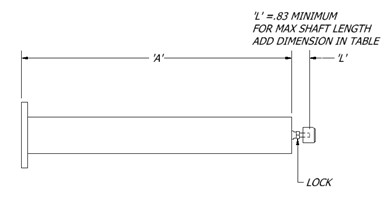

The sliding load motion is controlled to a high degree of precision thru extremely accurate machining techniques. Travel of the termination is a minimum 1/2 wavelength at the lowest frequency enabling phase reversal. Provisions are provided to lock the termination at any position.

Waveguide Terminations:

Double Ridge Waveguide Terminations

Waveguide Terminations

Water Cooled Terminations

Coaxial:

Coaxial Terminations

Ka-Band:

Ka-Band Coaxial Terminations

Ka-Band Waveguide Terminations

| Rectangular Waveguide Sliding Termination, Low Power - 721 Series | ||||||

|---|---|---|---|---|---|---|

|

TYPICAL SPECIFICATIONS Electrical |

|||||

| WG Size | Freq. (GHz) | VSWR Max |

Avg. Power (Watts) |

Standard Model No.* |

Minimum Travel (Inches) |

Dim A (Inches) |

| WR430 | 1.70 - 2.60 | 1.020 | 8.0 | 430-721A-2 | 6.00 | 23.00 |

| WR340 | 2.20 - 3.30 | 1.020 | 7.0 | 340-721A-2 | 4.50 | 18.00 |

| WR284 | 2.60 - 3.95 | 1.020 | 5.0 | 284-721A-6 | 4.00 | 17.50 |

| WR229 | 3.30 - 4.90 | 1.020 | 3.0 | 229-721B-2 | 3.00 | 13.50 |

| WR187 | 3.95 - 5.85 | 1.020 | 3.0 | 187-721A-6 | 2.50 | 12.00 |

| WR159 | 4.90 - 7.05 | 1.020 | 3.0 | 159-721B-2 | 2.00 | 11.00 |

| WR137 | 5.85 - 8.20 | 1.020 | 2.0 | 137-721B-2 | 1.75 | 10.00 |

| WR112 | 7.05 - 10.0 | 1.020 | 2.0 | 112-721B-6 | 1.60 | 9.00 |

| WR102 | 7.00 - 11.0 | 1.025 | 2.0 | 102-721A-6 | 1.50 | 8.75 |

| WR90 | 8.20 - 12.4 | 1.025 | 2.0 | 90-721A-6 | 1.30 | 8.00 |

| WR75 | 10.0 - 15.0 | 1.025 | 2.0 | 75-721B-6 | 1.00 | 7.50 |

| WR62 | 12.4 - 18.0 | 1.030 | 1.0 | 62-721B-6 | 0.75 | 6.50 |

| WR51 | 15.0 - 22.0 | 1.040 | 0.5 | 51-721B-6 | 0.65 | 6.00 |

| WR42 | 18.0 - 26.5 | 1.040 | 0.5 | 42-721B-6 | 0.55 | 5.50 |

| WR34 | 22.0 - 33.0 | 1.040 | 0.5 | 34-721B-6 | 0.50 | 5.00 |

| WR28 | 26.5 - 40.0 | 1.040 | 0.5 | 28-721B-6 | 0.45 | 4.50 |

|

* The Standard Model Numbers above are the most common parts ordered for size, material and flange. However, these models can easily be altered for your needs by using the Model # code system at left. |

||||||||||||||||||||||||||||||